Singaporean scientists have developed 3D printing technology for concrete that can capture carbon dioxide

Scientists at Nanyang Technological University (NTU) in Singapore have developed an innovative method for 3D printing concrete that can capture and store carbon dioxide. This technology promises to reduce environmental damage caused by the construction industry, which accounts for about 8% of global CO2 emissions.

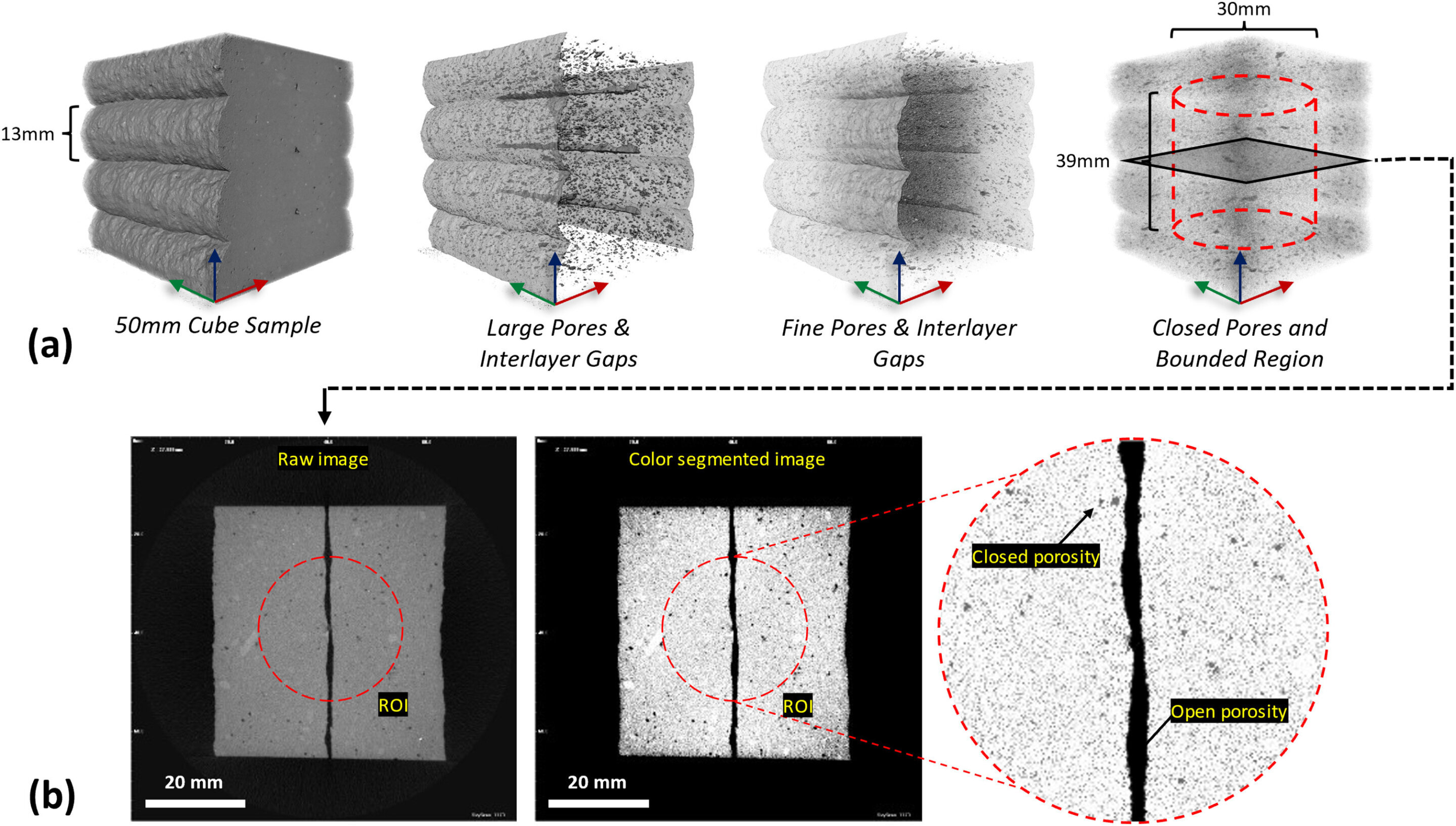

The method is based on injecting water vapor and carbon dioxide, captured as by-products of industrial processes, into the concrete mixture during the printing process. Carbon dioxide reacts with the components of concrete, turning it into a solid form, allowing it to be stored within the material. In addition, steam also enhances the ability to absorb CO2, improving the properties of concrete.

Tests showed that the compressive strength of this type of concrete increased by 36.8% and the flexural strength increased by 45.3% compared to conventional 3D printed concrete. New technology has also improved the material's flexibility and resistance to pressure, making it more reliable.

According to Professor Tan Ming Jen, who led the research, the new system not only reduces carbon emissions but also demonstrates the possibility of using carbon dioxide emissions from power plants or factories to create materials. sustainable construction.

Study first author Lim Sean Gip said this is an important step towards achieving climate goals and the technology could help make building greener. Study co-author Dr. Daniel Tay added that this technique enables the construction of greener, more durable buildings, driving innovation in the construction industry.

© Carbon Capture Science & Technology

© Carbon Capture Science & Technology